Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Powder classifiers are invaluable for the selection of a required particle size range to achieve a more consistent material and product performance.

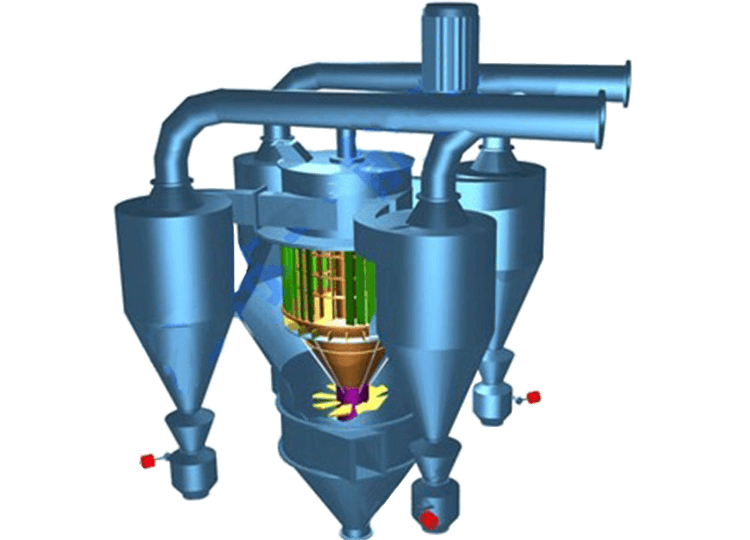

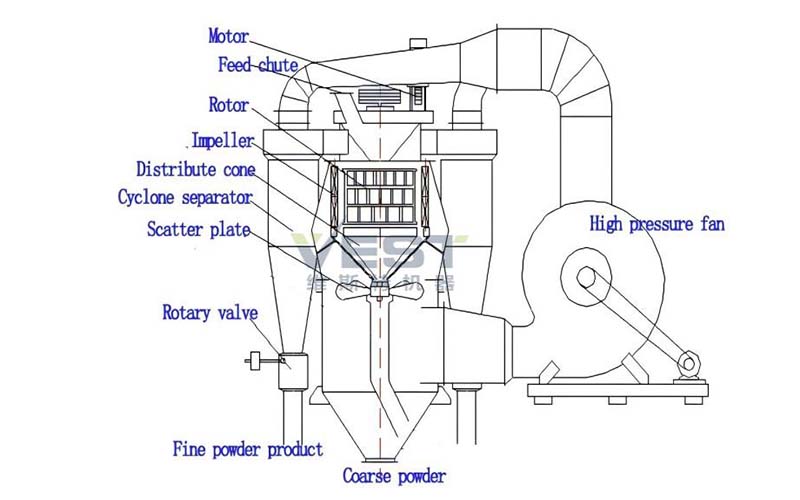

The high-efficiency powder classifier adopts the organic combination of gravity centrifugal and cyclone vortex multiple classification force fields, with high classification accuracy. The cage rotor is set to help the accumulated particles to be lifted up again, increase the classification capacity, and effectively reduce the fine powder content in the coarse powder.

The T-Sepax powder classifier adopts two-stage sorting and three-stage dispersion, which can "divide the material into three," with high classification accuracy and classification efficiency of more than 85%.

Reasonable structure allows powder selection air volume , output and feed amount vary in a large range without affecting powder selection efficiency, and its classification performance is very stable.

The powder classifier rotor is equipped with an eddy current rectifier that makes the gas flow field on the surface of the classification circle uniform and stable; the relative error of the airflow at any point is <5%.

The inner lining of the powder selector adopts a new type of manganese plate, which effectively extends its service life.

Powder classifiers are widely used in chemical, mining, building materials, food, medicine and other industries to accurately classify the particle size of various dry powder materials.

Air classifiers often work with ball mills, forming a closed-circle production plant. it can improve ball mill capacity and get the required material size. More than 300 mesh powders can be obtained.

In the working conditions, a high-speed motor drives the vertical transmission shaft to rotate through the transmission device. The material accesses the chamber of the separator by the feeding port on the top of the separator, and then falls on the scattering plate by two pyramidals, which are set in the coarse powder collecting cone and powder pipe.

The fine powder that satisfies demand will enter inside through the cage rotor, with circulating air entering the high efficiency and low resistance cyclone separator, then slip into the fine powder collecting cone into a finished product.

*The output will vary according to different materials, feed particle size and other factors

| Model | TS400 | TS500 | TS600 | TS700 | TS900 | TS1000 | TS1100 | TS1200 | |

| Matched mill (m) | Φ1.5 | Φ1.83 | Φ2.2 | Φ2.4 | Φ3.0 | ||||

| Motor Blower | Model | YCTL200-4A | YCTL200-4B | YCTL200-4A | YCTL200-4B | YCTL200-4B | YCTL200-4A | YCTL200-4A | YCTL200-4B |

| Rotating speed(r/min) | 125-1250 | 132-1320 | 440-1340 | 440-1340 | 600-1340 | ||||

| Power (KW) | 7.5 | 11 | 15 | 18.5 | 37 | 55 | 75 | 90 | |

| Model | SCF-12NO.8C | SCF-12NO.8C | SCF-12NO.10C | SCF-12NO.12C | SCF-12NO.12C | SCF-12NO.16B | SCF-12NO.16D | SCF-12NO.12C | |

| Volume | 24216 | 30900 | 37960 | 58200 | 119332 | 168000 | 192000 | 211000 | |

| Air pressure | 2.18 | 2.43 | 2.34 | 2.07 | 2.26 | 2.70 | 2.70 | 2.60 | |

| Rotating speed(r/min) | 1500 | 1600 | 1200 | 1000 | 800 | 960 | 960 | 710 | |

| Model | Y180M-2 | Y200L1-2 | Y225S-4 | Y225M-4 | Y335M1-8 | Y335M1-6 | Y335M3-6 | Y335L-8 | |

| Power (KW) | 22 | 30 | 37 | 55 | 132 | 160 | 200 | 220 | |

| Rotating speed of shaft (r/min) | 190-380 | 190-380 | 150-350 | 150-350 | 140-350 | 100-300 | |||

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.