Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

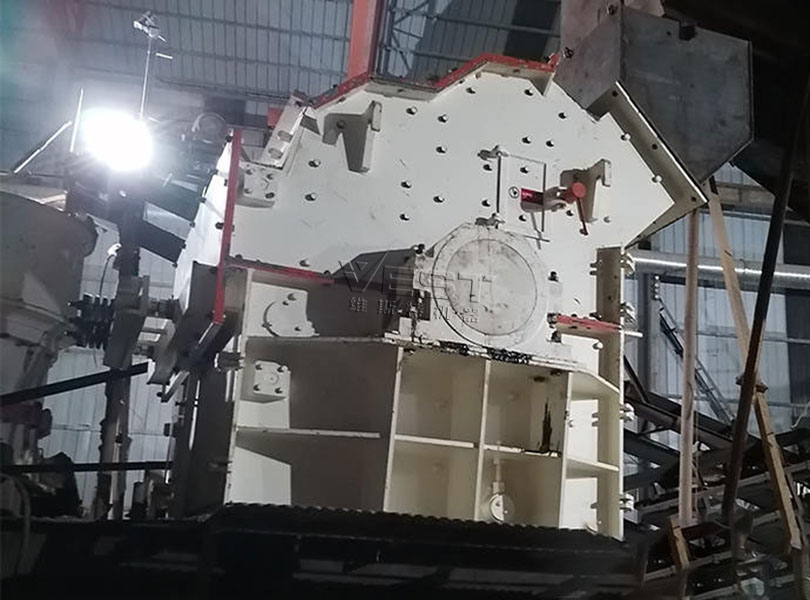

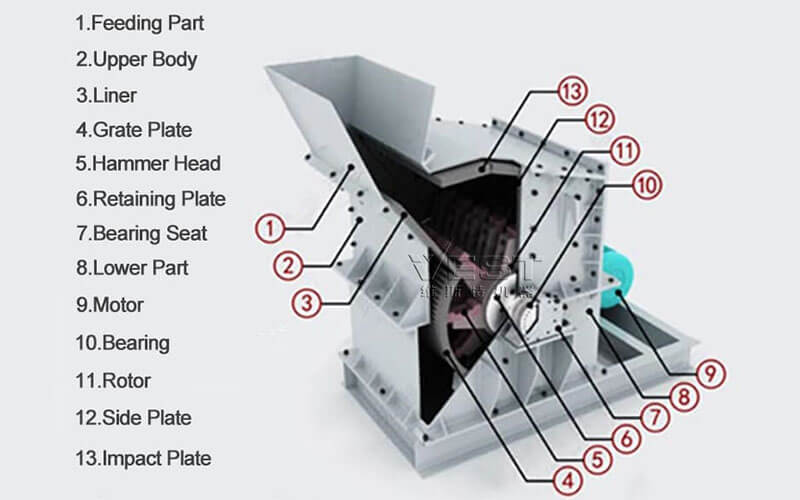

PCX high-efficiency fine crusher is a new type of fine crushing equipment that combines hammer and impact crushing technologies. It is suitable for medium-hard materials with compressive strength ≤200MPa such as limestone, shale, cement clinker, etc. The output particle size can be as fine as less than 3mm with high uniformity. It is widely used in building materials, metallurgy, chemical industry and other fields.

PCX high-efficiency fine crusher can crush medium-to-high hardness stones with Mohs hardness ≤ 7 (such as granite, basalt, pebbles, etc.). The single machine output reaches 20-300 tons/hour, and it has both efficient crushing and particle shape optimization capabilities.

The unique rotor structure and hammer layout, combined with the high-speed impact crushing principle, significantly improve the material handling capacity and crushing efficiency.

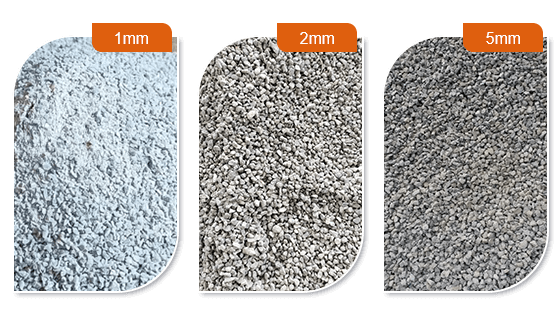

Through the collision between the multi-stage crushing chamber and the material self-lining, needle-like particles are reduced and high-quality aggregates with round particles and reasonable grading are produced.

The optimized rotor dynamics design and energy-saving motor configuration reduce unit energy consumption and save operating costs while ensuring production capacity.

The use of high manganese steel hammer head, wear-resistant lining and other materials, combined with modular structure design, can extend the service life of the equipment and facilitate maintenance and replacement.

PCX high-efficiency fine crusher is widely used in construction aggregate, machine-made sand production, mine tailings treatment and chemical metallurgical raw material processing. It is suitable for large-scale material processing needs in the fields of railways, water conservancy, concrete mixing stations, etc.

The PCX high-efficiency fine crusher uses high-speed rotating hammers to perform multi-stage impact crushing on materials.

After the material enters the crushing chamber, it is first hit violently by the high-speed rotating hammer, and then thrown onto the impact liner for further collision and fragmentation. Through repeated impact, grinding and self-collision between materials in the multi-stage crushing chamber, it is gradually refined to the target particle size (such as less than 3mm).

In addition, the impact plate inside the equipment can adjust the gap and flexibly control the discharge particle size. Combined with the multi-chamber design, the crushing path is optimized to achieve high efficiency, energy saving and uniformity of the finished product.

*The output will vary according to different materials, feed particle size and other factors

| Model | Feeder Opening Size (mm) | Max Feeding Size (mm) | Output Size (mm) | Capacity of Cement (t/h) | Capacity of Limestone (t/h) | Motor Power(kw) |

| PCX0804 | 400×185 | ≤120 | ≤3(85%) | 20-30 | 35-45 | 45 |

| PCX0806 | 500×250 | ≤180 | ≤3(85%) | 35-40 | 45-55 | 55 |

| PCX0808 | 550×330 | ≤180 | ≤3(85%) | 35-40 | 55-65 | 55 |

| PCX1010 | 1000×350 | ≤180 | ≤3(85%) | 45-55 | 65-75 | 75 |

| PCX1210 | 1200×400 | ≤180 | ≤3(85%) | 50-100 | 80-100 | 110 |

| PCX1212 | 1200×450 | ≤180 | ≤5(85%) | 90-100 | 100-110 | 132 |

| PCX1414 | 1500×500 | ≤190 | ≤5(85%) | 100-150 | 100-150 | 160 |

| PCX1616 | 1600×550 | ≤190 | ≤5(85%) | 170-210 | 190-250 | 250 |

| PCX1818 | 1800×800 | ≤190 | ≤5(85%) | 250-270 | 280-310 | 315 |

***The capacity will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

Have Any Questions!

Don't Hesitate To Contact Us Anytime.