Phone/Wechat/Whatsapp:+86-15538359886

Phone/Wechat/Whatsapp:+86-15538359886

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Phone/Wechat/Whatsapp:+86-15538359886

Phone/Wechat/Whatsapp:+86-15538359886

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

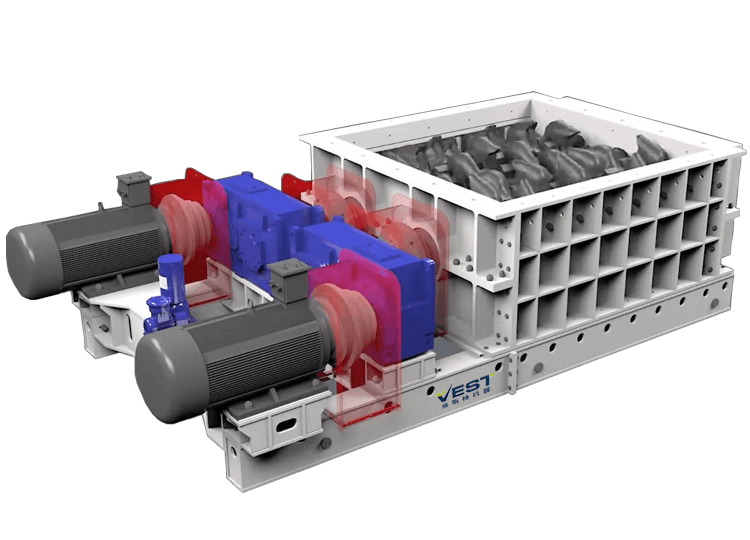

VEST mining mineral sizers is easy to maintain, stable in operation, high in output, and can process both wet sticky materials and dry hard rocks.

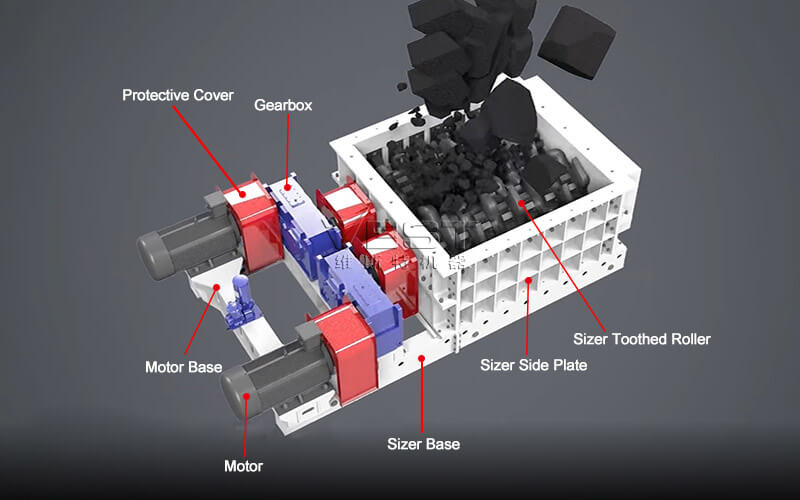

The mineral sizers is mainly composed of a driving device, a gear roller, a meshing gear, a housing, a base, a lubrication device and other parts. VEST mineral classifier is specially designed for crushing hard rocks such as gold ore, bauxite, copper ore, limestone, etc. It is particularly suitable for crushing stones with sticky clay.

VEST mining sizer can accurately control the product particle size and effectively reduce the generation of fine powder. While increasing production, it also reduces the amount of fine powder and dust generated.

The mining mineral sizer has a very compact size, making it easy to install in a small space, which reduces the installation cost a lot.

The mineral sizers has a simple structure, reliable design, few wearing parts, and is easy to carry out simple, safe and fast inspection and maintenance, which can shorten the time and effectively improve productivity.

VEST mining mineral sizer can realize remote and automated operation, which not only ensures the best performance but also ensures the safety of operation.

At present, our mineral sizer crusher is widely used in open-pit mine coal feeding system, coal transportation plant, limestone, ore crushing system and other fields.

Material is gripped and broken initially between the leading faces of opposed teeth.

Material drawn down into the second stage is broken into smaller pieces by the smaller pockets created by the leading teeth on one shaft and the rear faces of teeth on the other shaft.

Any remaining oversize or slabby pieces are finally broken as the teeth rotate past the fixed teeth of the Breaker Bar - The third and final stage of breaking.

*The output will vary according to different materials, feed particle size and other factors

| Model | 2PLF800 | 2PLF1000 | 2PLF1200 | 2PLF1500 |

| Teeth Roller Dia (mm) | 800 | 1000 | 1200 | 1400 |

| Roll length (mm) | 1500-2500 | 1500-3000 | 1500-3000 | 2000-3500 |

| Max feed size (mm) | 800 | 1000 | 1200 | 1500 |

| Output size (mm) | ≤300 | ≤300 | ≤300 | ≤300 |

| Capacity (t/h) | ≤2000 | ≤3500 | ≤6000 | ≤10000 |

| Model | 2PLS800 | 2PLS800 | 2PLS1000 | 2PLS1200 |

| Teeth Roller Dia (mm) | 600 | 800 | 1000 | 1200 |

| Roll length (mm) | 1000-2500 | 1500-3000 | 2000-3500 | 2000-4000 |

| Max feed size (mm) | 200 | 300 | 350 | 400 |

| Output size (mm) | 50-80 | 50-100 | 50-120 | 50-140 |

| Capacity (t/h) | 250-800 | 500-2000 | 600-3000 | 800-4000 |

Have Any Questions!

Don't Hesitate To Contact Us Anytime.