Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

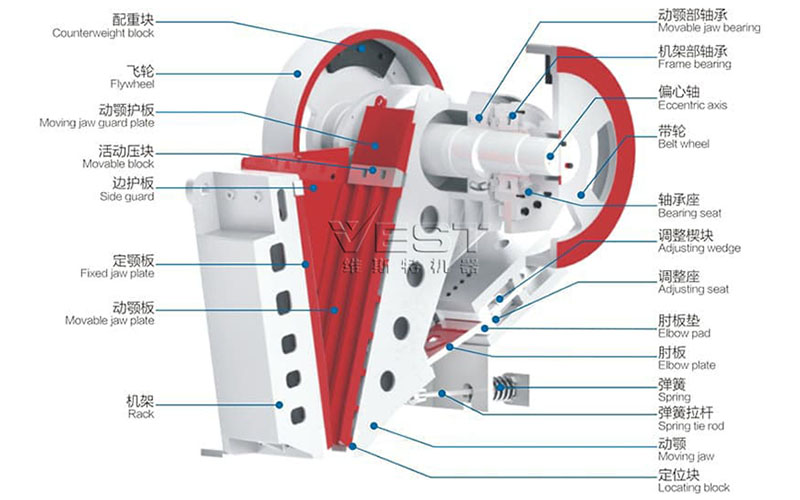

C Series Jaw Crusher have a strong pinned and bolted, non-welded frame construction, which brings benefits to stationary underground and mobile crushing applications. our designs comply with original safety standards and have the advantages of high output, low energy consumption, reliable structure, easy operation and maintenance, and long service life.

C Jaw Crusher main accessories include: Its main accessories include: fixed jaw plate, movable jaw plate, side guard plate, elbow plate, eccentric axis, bearings, rack, flywheel, tie rods and various bolts, nuts and other fasteners.

The details about the materials of these parts are as follows:

Materials of Main Structural Parts

1. Fixed Jaw Plate and Movable Jaw Plate:

These parts usually need to withstand greater impact and wear, so often use high hardness, high toughness materials, generally use high manganese steel, our company chose MN13CR4 material, the effect is more wear-resistant than the general.

2. Elbow Plate:

As an important force transmitting part in the crusher, the elbow plate also needs to have high strength and toughness, generally using gray cast iron, used to protect the equipment, when there is more than the crushing capacity of the large pieces of material into the elbow plate will break, to prevent damage to the crusher.

Auxiliary Parts Material

1. Side Guards:

In order to protect other parts of the jaw crusher machine from wear and tear, the guards are usually made of better wear-resistant materials, such as high manganese steel, alloy steel or composite materials.

2. Eccentric Axis:

Usually high strength forged steel is used to ensure the normal movement of the movable jaw and the overall strength of the crusher.

3. Bearings:

Bearings are the key parts in the crusher, which need to withstand large loads and friction, so high quality heavy-duty rolling bearings are used to ensure the stable operation of the equipment.

4. Bolts and Tie Rods:

These parts are used to connect and fix the various parts of the crusher, which need to withstand large tensile and shear forces, so they are often made of high-strength alloy steel.

5. Others:

including various bolts, nuts and other fasteners, used to fix each component.

It is important to note that different manufacturers and models of C series jaw crusher may have differences in the material of the accessories. Therefore, when purchasing accessories, it is recommended to refer to the manual of the specific equipment or consult the manufacturer for accurate information.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online