Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Granite is a common mineral rock, mainly composed of quartz, feldspar and mica and other minerals, and its color is diverse, common gray, flesh red, greenish gray and so on. Granite is hard, wear-resistant, pressure-resistant, fire-resistant, acid-resistant, alkali-resistant and resistant to corrosive gases, so it is widely utilized in construction, decoration and other fields.

For granite crushing, the following types of Stone Crusher Equipment are better choices:

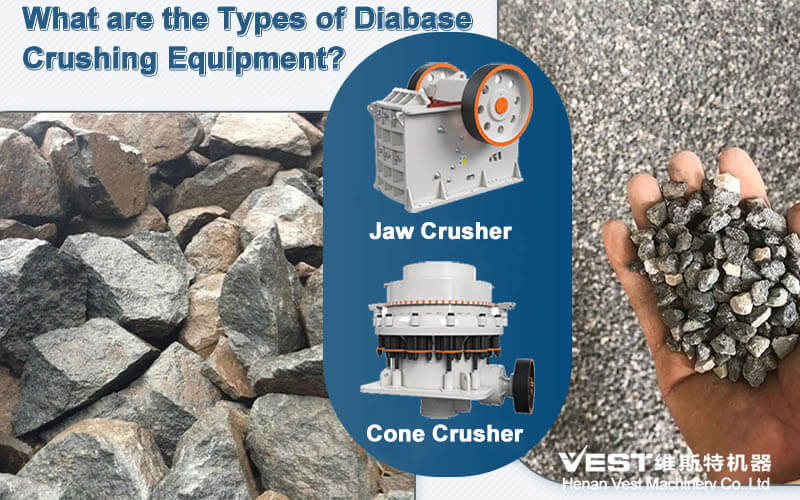

1. Jaw Crusher Machine

C Jaw Stone Crusher is commonly used for primary crushing, and can handle larger rocks. The crushing method is simple and effective, which is very suitable to deal with the hardness of granite. Meanwhile, jaw crusher is the first choice for most customers because of its simple structure, stable productivity, easy maintenance and economical operation cost.

2. Cone Crusher

Cone crusher is usually used for secondary or tertiary crushing, with high crushing ratio and production efficiency. For the hardness of granite, you can choose composite cone crusher, which has stronger wear resistance and crushing capacity. The crushing cavity of the cone crusher is reasonably designed, and the size of the crushed product is even, which is especially suitable for dealing with hard stones like granite.

3. Impact Crusher

Impact crusher is mainly used for secondary crushing, both crushing and shaping dual function, suitable for materials below medium hardness. Although granite has high hardness, after primary crushing by jaw crusher or cone crusher, impact crusher can be used for further crushing to get better granularity of finished products. Impact crusher is famous for high efficiency, high crushing ratio, low energy consumption, high output and even particle size.

4. Hammer Crusher

Hammer crusher is suitable for crushing brittle materials, such as granite. Hammer crusher has high crushing efficiency, and the gap between hammer head and liner plate can be adjusted according to the need to control the size of finished products.

5. Sand Maker Machine

In granite crushing production line, sand making machine is usually used to further finely crush the crushed pieces that meet the requirements of sand making into sand in order to meet the specific particle size requirements.

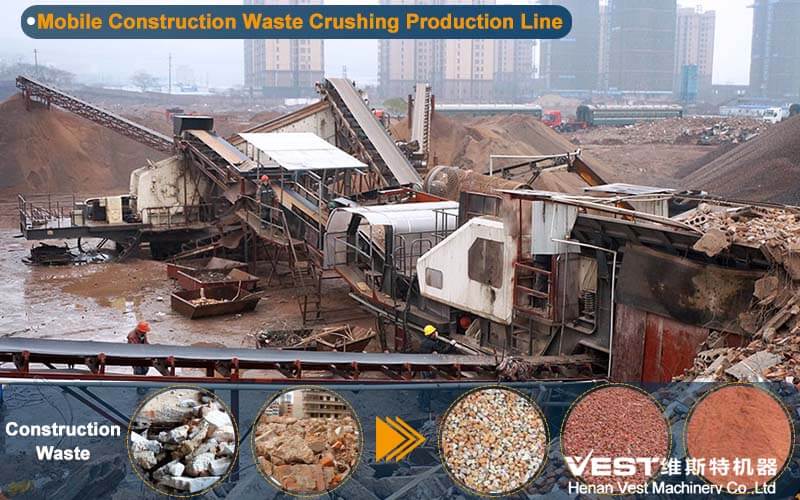

6. Mobile Crushing Plant

Mobile Stone Crusher is a mobile stone crushing plant, which can be easily moved inside and outside the production site, and is very suitable for large open granite quarries. The mobile crusher can be directly stationed in the quarry or aggregate yard and transferred at any time, saving the transportation cost. mobile crusher can be configured according to your needs.

In the actual selection, comprehensive consideration should be given to the characteristics of granite, output requirements, finished product size and investment costs and other factors. At the same time, the process of using multiple equipment in conjunction with each other can also be considered to achieve the best crushing effect.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online