Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Diabase, also known as coarse-grained basalt, is a basic, shallow-sedimentary, intrusive igneous rock. Its primary mineral components are pyroxene and basic plagioclase, and its chemical and mineralogical composition is consistent with gabbro. Its texture is finer than gabbro, it contains more ferromagnesian minerals, and its color is darker. It is also highly wear-resistant and corrosion-resistant.

After processing and crushing, diabase has a wide range of uses, attracting numerous investors.

So, what are the different types of diabase crushers? What are the uses of crushed diabase? Below, VEST Machinery will provide a detailed introduction.

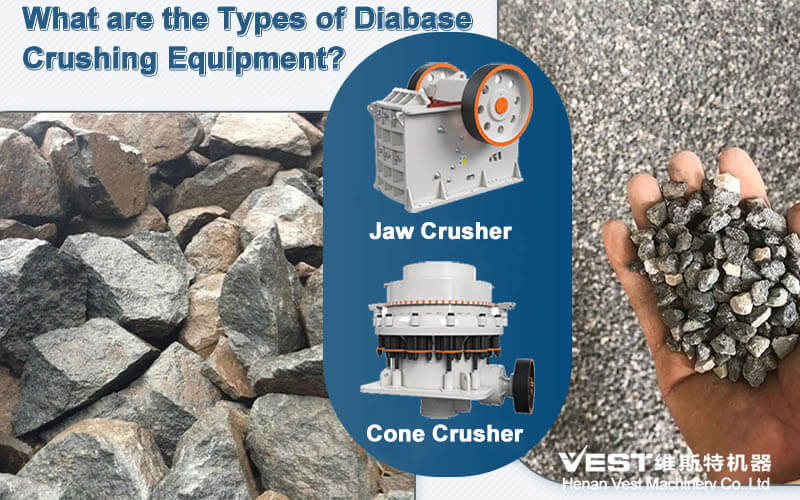

What Crushing Equipment Can be Used to Crush Diabase?

Diabase has a Mohs hardness of 6 or above, making it a hard rock. Therefore, the following crushers are recommended for crushing diabase:

The relative motion between the movable and fixed jaw plates compresses and splits the material, achieving crushing. Featuring a high reduction ratio and strong impact resistance, it is suitable for primary crushing of large diabase blocks, serving as the first coarse crushing step in a production line.

The following are the main accessories for a jaw crusher:

Consumable Part Name | Material | Service Life (Months) |

Crushing Plates of Moving/Fixed Jaw | Manganese Steel | 4 |

Front and Rear Thrust Plates | Cast Steel | 24 |

Thrust Plate Support Seat | Carbon Steel | 10 |

Eccentric Shaft Bearing Bushing | Alloy | 36 |

Moving Jaw Suspension Shaft Bearing Bushing | Bronze | 12 |

2. Secondary Crushing CS Symons Cone Crusher:

Using the laminated crushing principle, the crushing process involves mutual compression, bending, and friction between the moving and fixed cones. It is suitable for high-hardness diabase.

The following are the main accessories for cone crushers:

Consumable Part Name | Material | Service Life (Months) |

Crushing Wall | Mn13, Mn18Cr2 | 6 |

Molding Moulding Wall | Mn13, Mn18Cr2 | 6 |

Liner | Carbon Steel | - |

Bushing | High Manganese Steel, Iron-Carbon Alloy, Tungsten Alloy | - |

3. Fine Crushing VSI Vertical Shaft Impact Crusher:

Using both "rock-on-rock" and "rock-on-iron" crushing methods, it is suitable for high-quality material requirements. The finished sand produces fine grain shape and a shaped finish, meeting the needs of high-end building materials.

The following are the main components of an impact sand making machine:

Consumable Part Name | Material | Service Life (Months) |

Impeller | High manganese steel, high chromium cast iron | - |

Guard Plate | High manganese steel, alloy steel | - |

Liner | High manganese steel | 36 |

Rotor | Alloy steel, high chromium 26 alloy | - |

V-Belt | Polyester tempered coir, rubber, nylon | - |

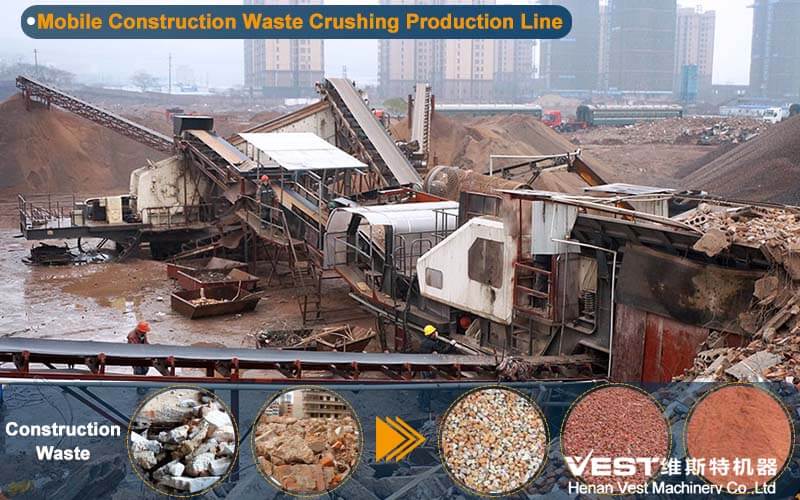

The typical process of a diabase crushing line is as follows: diabase ore passes through a vibrating feeder into a jaw crusher for coarse crushing, followed by a cone crusher for secondary and fine crushing. Vibratory screening is then used to select different particle sizes, and finally, a sand-making machine further processes the ore into high-quality finished sand.

Diabase Has a Wide Range of Uses, Including:

1. Building Materials:

Diabase is a high-quality building material. Those with a uniform texture and no cracks can be used as raw stone.

2. Wear-Resistant Materials:

Diabase can be used to manufacture wear-resistant liners, wear-resistant balls, and other materials, and is widely used in industries such as metallurgy and mining.

3. Concrete Aggregate:

Diabase can be used as an aggregate in concrete, improving its strength and wear resistance.

4. Road Construction:

Diabase is a commonly used aggregate in road construction, used for roadbeds and pavements. For example, it is widely used in railway foundations, municipal engineering stone, crushed stone for asphalt concrete, and airport runway aggregate. It exhibits excellent stability and durability.

5. Chemical Raw Material:

Diabase can also be used as a raw material in certain chemical production processes.

As such, diabase not only has significant value in crushing and processing, but also has a wide range of applications due to its excellent physical and chemical properties.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online