Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Selecting a PE jaw crusher machine suitable for your mine requires comprehensive consideration of several factors to ensure that the equipment can meet the production requirements and have good performance. Here are some specific suggestions for selection:

Define The Material Characteristics

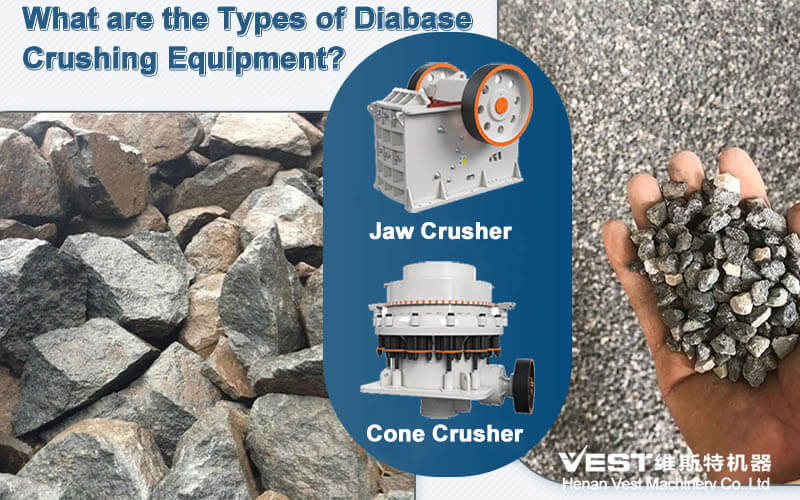

1. Hardness: The hardness of the ore is one of the key factors in determining the selection of a jaw crusher. Higher hardness of the ore requires choosing a higher compressive strength of the jaw material, such as tungsten carbide.

2. Humidity and mud content: These factors may affect the crushing efficiency and equipment wear, so you need to consider the humidity and mud content of the material when selecting the right equipment cavity type and material.

Match The Capacity Demand

1. According to the capacity demand of the production line, choose the jaw crusher with the corresponding processing capacity. For example, the PE-600×900 Jaw Crusher has a capacity of 90-180t/h, which is suitable for most of the customers as well as medium and large production lines.

2. Considering the fluctuation of capacity, a certain margin should be reserved when selecting the model to ensure the stable operation of the equipment during the peak period.

Adapt to The Site and Material Requirements

1. Customize the design of the inlet and outlet size to adapt to the layout of the existing production line and space constraints.

2. According to the requirements of the discharge size, select the appropriate discharge opening adjustment device and model to ensure that the size of the crushed product is uniform and meets the production requirements.

Investigate Equipment Performance and Manufacturer Strength

1. When purchasing, you should go to the manufacturer's site for inspection to understand the actual operating conditions of the equipment, performance differences, and the manufacturer's technical strength and after-sales service.

2. Choose manufacturers with rich production experience and good market reputation to ensure the quality and reliability of the equipment.

Consider Energy Saving, Environmental Protection, and Long-term Benefits

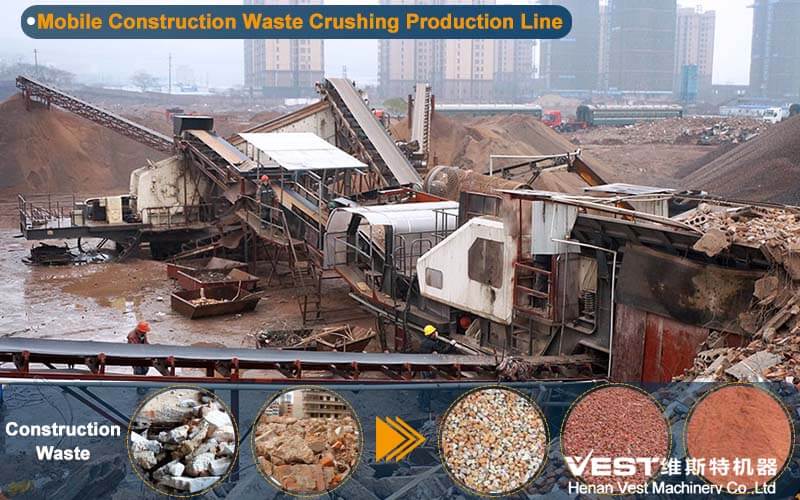

1. Choosing an energy-saving and environmentally friendly Stone Crusher Machine not only improves the efficiency of the equipment and saves electricity, but also reduces environmental pollution, which is in line with the requirements of sustainable development.

2. When selecting the model, the initial investment cost, operation cost, and long-term benefit of the equipment should be considered comprehensively, and the cost-effective model should be chosen.

To summarize, choosing a PE jaw crusher suitable for mining requires comprehensive consideration of material characteristics, capacity requirements, site and discharge requirements, equipment performance, manufacturer strength, as well as energy saving, environmental protection, and long-term benefits, and other factors. Through comprehensive analysis and evaluation, we can ensure that the selected equipment can meet the production requirements and has good performance.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online