Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Classification of Stone Crusher Machine:

The common Stone Crusher Machine in mining machinery are mainly divided into two categories according to the crushing principle:

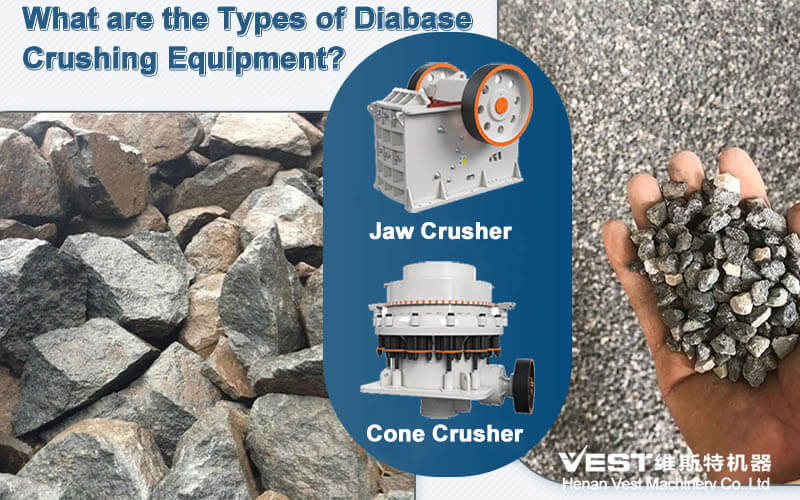

1. One is the extrusion crushing equipment (static pressure crushing), such as jaw crusher, cone crusher, etc., which is suitable for crushing raw materials with high wear index. The advantages are: it can handle high hardness materials (Mohs hardness ≥ 7) and long wear parts life. But the product has a high needle-like proportion (about 15-25%).

2. The other is the impact crushing equipment (dynamic pressure crushing), such as impact crusher, hammer crusher, vertical shafter impact crusher, etc. Its characteristics are large material crushing ratio, simple structure, convenient equipment maintenance, good finished product particle shape, and small loss of material compressive strength. But it is not suitable for highly abrasive materials.

In large-scale sand and gravel production lines, jaw crushers are usually used for coarse crushing, while cone crushers, impact crushers or hammer crushers are used for medium crushing.

Next, Vest Machine will analyze the advantages and disadvantages of the four common stone crushers in mining machinery for your reference.

Advantages and Disadvantages of 4 Common Stone Crusher Machine:

Advantages: simple structure, reliable operation, small size, light weight, low configuration height, large feed port, adjustable flow, low price;

Disadvantages: fast wear of lining, poor product grain shape, many pin plate shapes, low output, and forced feeding is required;

Scope of Application: good adaptability to rock hardness, generally used for coarse crushing of raw materials, and medium crushing equipment needs to be miniaturized.

Advantages: reliable operation, high output, uniform particle size, and small wear of lining;

Disadvantages: complex structure, high maintenance requirements, large installation size, and high price;

Scope of Application: good adaptability to rock hardness, the most commonly used medium and fine crushing equipment on the aggregate production line.

Advantages: large crushing ratio, fine product, good grain shape, low energy consumption, simple structure;

Disadvantages: steel plate hammer and liner are easy to wear, replacement and maintenance workload is large, dust is serious, not suitable for crushing plastic and sticky materials;

Scope of application: suitable for crushing medium-hard rock, medium crushing and sand making equipment, and some large equipment is currently used for coarse crushing.

4. Hammer Crusher

Advantages: large crushing ratio, high output, good grain shape, fine material;

Disadvantages: hammer damages quickly, frequent replacement, large working dust, raw material moisture content exceeds 12%, and rubber cannot pass effectively;

Scope of Application: suitable for crushing medium-hard rock, generally used for fine crushing equipment; when there is a grate, it is used for sand making, and is rarely used at present.

If you need a stone processing production line, please Contact Us. VEST engineering team and management team will provide services for your project and issue detailed layout drawings.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online