Warm Tip :

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

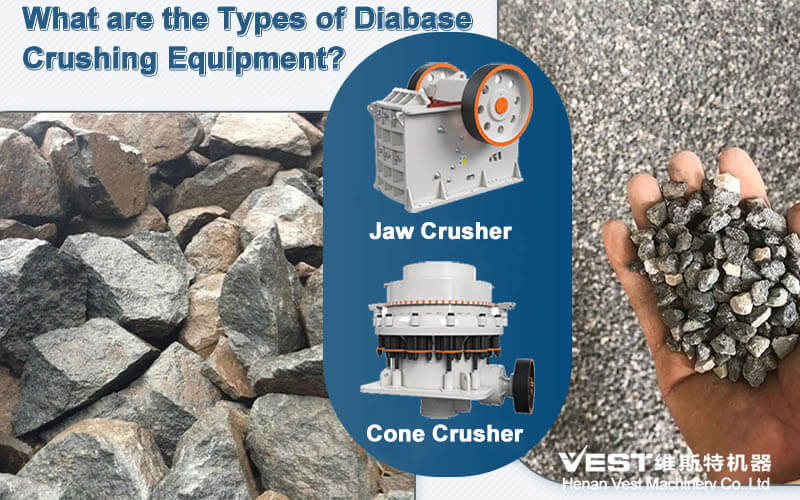

Jaw Stone Crusher, also known as Rock Jaw Crushing Machine, is a common coarse crushing equipment. It is mainly used as a head crusher in mining equipment and is often used to crush ores, rocks and other stones with higher hardness.

At present, the price of a Small Jaw Crusher is about several thousand dollars, and it is completely fine to use it for 2-3 years. However, the jaw crusher needs to be frequently inspected and maintained during use so that it can be used for a longer time.

Extending the service life of the jaw crusher is the key to reducing production costs and improving production efficiency. Below VEST Machinery provides several methods and suggestions for extending the service life of the jaw crusher for your reference.

1. Correct Operation and Use

⋅ Standard Operation: Operators must undergo professional training and strictly follow the equipment operating procedures to avoid equipment damage due to misoperation.

⋅ Uniform Feeding: Use a vibrating feeder to feed evenly to avoid large pieces of material directly impacting the jaw plate, causing equipment overload or damage.

⋅ Control The Feed Size: Ensure that the feed size does not exceed the maximum feed size allowed by the equipment to avoid blockage or overload.

2. Regular Maintenance and Care

⋅ Lubrication and Maintenance:

Regularly check the lubrication system to ensure that key parts such as bearings and elbow plates are well lubricated.

Use lubricating oil that meets the requirements of the equipment and replace it regularly.

⋅ Tighten Bolts:

Regularly check the bolts of various parts of the equipment to ensure that they are tightened to avoid loosening and causing vibration or damage to the equipment.

⋅ Clean Equipment:

Regularly clean the accumulated materials and debris inside the equipment to avoid blockage or wear.

3. Inspection and Replacement of Key Components

⋅ Jaw Plate:

Regularly check the wear of the jaw plate. When the wear reaches a certain level, replace or swap the position in time (swap the upper and lower jaw plates).

Choose jaw plates made of highly wear-resistant materials (such as high manganese steel) to extend the service life.

⋅ Toggle Plate:

Check whether the toggle plate has cracks or wear, and replace it in time if problems are found.

⋅ Bearing:

Regularly check the wear of the bearing and replace damaged bearings in time.

Avoid overheating of the bearing and ensure good lubrication.

4. Equipment Operation Monitoring

⋅ Monitoring The Operation Status:

Install vibration sensors and temperature sensors to monitor the operation status of the equipment in real time.

When abnormal vibration or temperature rise is found, stop the machine for inspection in time.

⋅ Avoid Overload:

Install overload protection device to automatically shut down the equipment when it is overloaded to avoid damage to the equipment.

5. Optimize the Working Environment of the Equipment

⋅ Dust Prevention Measures:

Install dust removal equipment around the equipment to reduce the erosion of dust on the equipment.

⋅ Moisture and Rust Prevention:

When the equipment is out of service for a long time, moisture and rust prevention measures should be taken to prevent key components from rusting.

⋅ Ambient Temperature:

Avoid running the equipment at extreme temperatures. High or low temperatures will affect the performance and life of the equipment.

6. Choose the Right Equipment Model

⋅ Matching Production Needs:

Choose the right equipment model according to production needs to avoid long-term overload operation of the equipment.

⋅ High-Quality Equipment:

Choose brands and equipment with reliable quality to ensure that the design and manufacturing process of the equipment meet the standards.

7. Regular Inspection and Overhaul

⋅ Minor Repair:

Perform minor repairs every week or month to check the wear of wearing parts and replace them in time.

⋅ Medium Repair:

Perform medium repair every six months or one year to comprehensively check all parts of the equipment and replace severely worn parts.

⋅ Overhaul:

Perform an overhaul every 2-3 years to fully disassemble, inspect and repair the equipment to restore equipment performance.

8. Operator Training

⋅ Skill Training:

Perform regular training for operators to improve their operating skills and maintenance awareness.

⋅ Safety Awareness:

Strengthen safety education to ensure that operators are familiar with the safe operating procedures of the equipment.

9. Use High-Quality Accessories

⋅ Original Accessories:

Try to use original accessories to ensure the quality and adaptability of accessories.

⋅ Wear-Resistant Materials:

Select wearing parts such as jaw plates and elbow plates made of highly wear-resistant materials to extend service life.

10. Records and Data Analysis

⋅ Operation Records:

Record the equipment’s operating time, maintenance status, fault handling and other information to facilitate the analysis of equipment usage.

⋅ Data Analysis:

Through data analysis, predict the equipment’s wear cycle and make maintenance plans in advance.

Whether it is a jaw crusher or other crushing equipment, you can follow the above method.

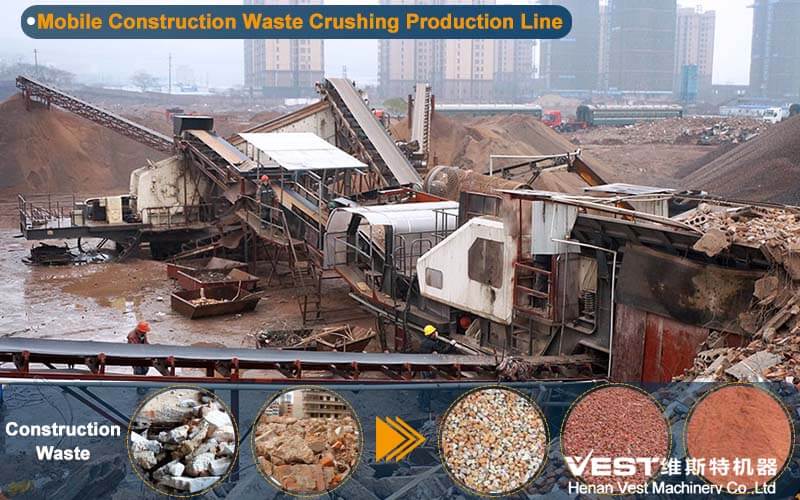

If you need a stone processing production line, please Contact Us. VEST engineering team and management team will provide services for your project and issue detailed layout drawings.

Phone/Wechat/Whatsapp:+86-19515530562

Phone/Wechat/Whatsapp:+86-19515530562

Email:crusher@hn-vest.com

Email:crusher@hn-vest.com

Message

Message Online

Online